About Company

Parv Metal Processing Company (PMPC) run by Technical Persons and has a vision to provide excellent quality by adding value engineering to all casted products.

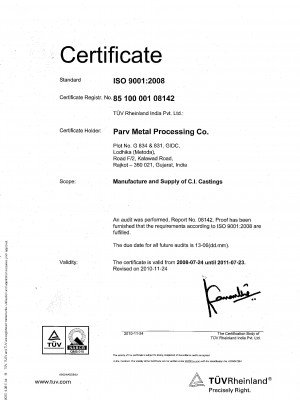

PMPC is an ISO 9001:2015 certified company from TUV Rheinland.

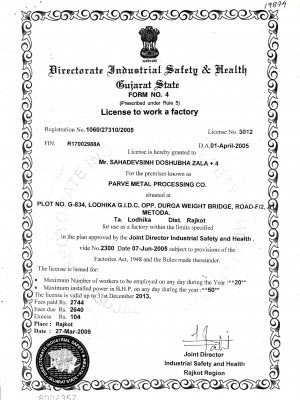

PMPC is located 15 kms away from Rajkot, in Lodhika GIDC at Metoda. Its hand & Machine molding division has facilities for manufacturing castings up to single piece weight of 7 MT. Capability to adapt to emerging trends and absorb new technologies, a competent metallurgy base and uncompromising quality has created a sound and solid base in the region. The company has commitment to produce consistent quality products and maintain time schedule.

Quality Policy

“PMPC” is committed to satisfy the customers with continuous improvement in the system by keeping everyone aware about the quality, application of product and system.

Quality Control

• Incoming Raw Material & in process casting Inspection.

• ISO certification (Regn No. 8510000108142)

• IEC 2405005239 & HS Code – 73259910

• Extensive used of FARO 3D Laser scanner and measuring arm. (fusion and quantum)

• Full-fledged laboratory with Spectrometer, Microscope, UTM, XRF & Sand testing lab.

Our Strength

• Partnership Firm and focus on Foundry business only.

• Extensive use of casting simulation software

• Supply of defect free products & timely delivery.

• Single piece casting weight from 500 KGs to 7000 KGs.

• No restriction about size & shape.

• Use of finest grade of raw material.

• Lesser in-house rejections.

• Well experienced man power.

• User of SAP, Soft cast (Casting Simulation software), Pro-E (Creo).

Sectorial Presence (Application Field)

PMPC is equipped to produce Grey Cast & Ductile iron casting for variety of application such as…

• CNC Machine Base, Column, Bed, Head Stocks, Slides, Saddles etc. (Machine tools)

• Turbine Parts

• Gearbox housing (Casing).

• Valve & Pumps Casing.

• Hydraulic & Power Press parts castings.

• Wind Energy Parts castings.

• Pressure test castings.